Problem

In the construction sector, there is a very high consumption of resources and so far a low reuse and recycling rate. When a building can no longer be used and is demolished, the construction waste is mostly disposed of in landfills or incinerated. A major cause of this is construction joints that are difficult or impossible to break and the use of a high percentage of composite materials. If buildings were deconstructed instead of demolished, the consumption of construction materials could reduce the depletion of primary resources. But how can this be implemented?

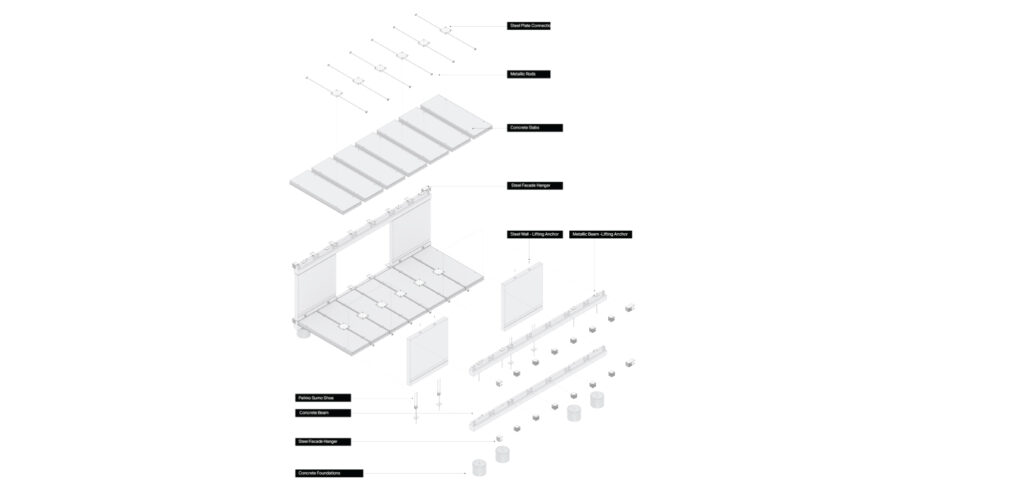

Generic description

The possibilities for recycling building components are very much determined by the method of construction. A design for disassembly also takes into account future uses as well as possible changes when choosing construction methods for the deconstruction of buildings. In this way, components, systems, and materials can later be recovered and reused when a building is deconstructed. By reusing, repairing, remanufacturing, recycling or upcycling them, environmental impacts can be minimised and economic value enhanced (Guy & Ciarimboli 2003, pp. 3-4). Biodegradation or energy recovery from the materials comes only last in the list of recovery options.

Fundamental to the design for dismantling is the development of a circular economy in which material cycles are closed – moving away from a linear economy. The goal is to achieve complete recovery of building materials and recyclables from the “urban ecosystem” in building construction. This requires the separation of material flows (Hillebrandt et al. 2018, p. 6). A particular challenge is the circular economy in the area of mineral building materials (Hillebrandt et al. 2018, p. 10). One example is the cradle-to-cradle principle, whereby reused and recycled materials are transformed into new ones. To minimise disposal, composting, or incineration from the future deconstruction process, ten key principles should be applied in the design in terms of reducing the consumption of resources, reusing and recycling (Guy & Ciarimboli 2003, p. 6):

- Document materials and methods for deconstruction.

- Select recyclable and renewable materials based on the precautionary principle.

- Design connections to be accessible.

- Minimise or eliminate toxic and insoluble connections.

- Use bolted, screwed, and nailed connections.

- Separate mechanical, electrical, and plumbing (MEP) systems.

- Design for the worker and the work of separation.

- Simplicity of structure and form.

- Interchangeability.

- Safe dismantling.

Example

In the Kalkbreite project, deconstructability and the possibility of conversion were already considered in the planning. Thus, a supporting structure consisting of a reinforced concrete skeleton construction with non-load-bearing exterior walls was realised as a front-mounted timber frame construction in order to be able to react to possible future needs with little effort. The timber frame structure was prefabricated, allowing for effective and fast site closure and system separation into primary, secondary and tertiary systems. Extension elements can be inserted without damaging adjacent building components. The technical dimensions for this were documented and are easily accessible. In addition, the materials were selected with regard to the absence of pollutants, recyclability and renewability.

A deconstruction and operating concept drawn up by the community was already included in the planning phase. In addition, a user manual for the building is available online for all to access (Genossenschaft Kalkbreite n.y.). This serves to provide information and to keep maintenance costs low.

Following the disassembly and cradle-to-cradle principle, the wood used in the “Solar Direct Gain House N11” is untreated and only wooden dowels and screw connections were used – no glue or composite materials were used. The sanitary objects come from a second-hand material store (Adam 2016, p. 45).

Lessons learned and synergies

The dismantling of components and materials aims to minimise environmental impacts through repair, reuse, material recovery and remanufacturing. It is an important strategy for saving raw materials (Rios et al. 2015, p. 1297). When this strategy is considered from the beginning, it allows for later flexibility, retrofittability, and deconstruction of the entire building. In addition, design for disassembly provides for the use of reusable, non-toxic and renewable materials to ensure sustainable buildings. The goal of efficient use of raw materials can also be achieved through avoidance, reduction, and longevity. Changed product design, circular economic processes and owner responsibility, new materials and re-design are all part of this, as are changes in user behaviour and reductive practices in building culture (Hillebrandt et al. 2018, p. 6).

During the planning stage of a building, it should already be clarified how materials used can be recycled, reused or, for example, returned at the end of their service life. Life cycle analyses can be helpful in this regard. In addition, the strategy of designing for disassembly can extend the useful life of a structure because repairs and renovation can be done with less impact on the overall building. Dismantling takes more time and costs than demolishing buildings-especially when buildings are constructed without considerations for reusing materials after the buildings’ useful life. One key to reducing costs is prefabrication and standardisation of building components, modular construction, and tracking of installed materials, such as through a material passport (Guy & Ciarimboli 2003, p. 4).

Sources

Adam, H. (2016): Ungehobelt. In: db deutsche bauzeitung 03/2016. Konradin Medien GmbH, 43-46. Accessed on 20.12.2021 from http://www.n11.ch/download/dt-bauzeitung3-16.pdf

Genossenschaft Kalkbreite (o.J.): Anleitung Kalkbreite. Richtig nutzen. Accessed on 20.12.2021 from https://anleitung.kalkbreite.staging-flake.tk/betrieb/richtig-nutzen.html.

Guy, B. & Ciarimboli, N. (2003): Design for Disassembly in the built environment. City of Seattle: WA, Resource Venture, Inc. Pennsylvania State University. Accessed on 18.12.2021 from https://www.lifecyclebuilding.org/docs/DfDseattle.pdf

Hillebrandt, A., Riegler-Floors, P. Rosen, A. & Seggewies, J.-K. (2018): Atlas Recycling. Recycling als Materialressource. 1. Auflage, München: Detail Business Information GmbH.

Rios, F. C., Chong, W. K., & Grau, D. (2015): Design for disassembly and deconstruction-challenges and opportunities. In: Procedia engineering, 118, 1296-1304.